Preventive and Breakdown Maintenance

Safety Work Permit

Asset and Spare Part Barcode

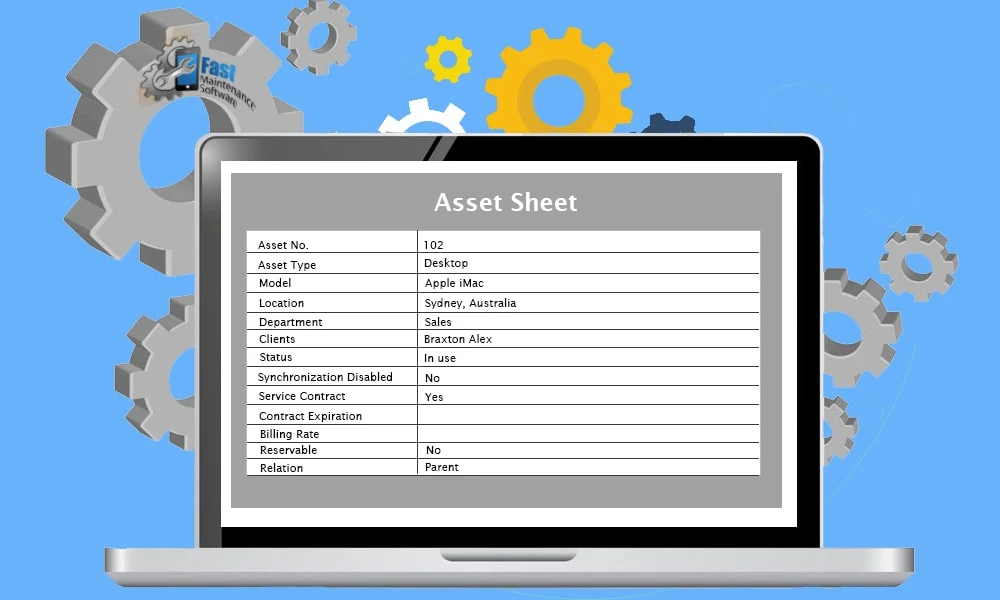

Web based maintenance management software has a built a robust maintenance management software with feature-rich tools for the Manufacturing, Construction, Healthcare industries, among others. To maximize performance, maintenance management software focuses on equipment records as their foundation.

Equipment records anchor most maintenance tasks and activities. You need to capture different types of information about your assets along with how they are used, where they are located and whether they are in service. Fast access to equipment information directly impacts your ability to provide effective maintenance.

This reduces the potential for introducing equipment failures while performing maintenance and saves time searching for the proper information. Another benefit of maintenance tracking is to get more accurate mean-time-between-failure data.Planned maintenance system helps managers have a better idea of the profitability of their assets and determine whether they are reaching their estimated lifespan.

The Fast Maintenance Management Software provides users with a set of tools needed to track and improve equipment performance in the factory. The system manages both scheduled and unscheduled equipment maintenance activities. Equipment Maintenance helps companies monitor and improve OEE(Overall Equipment Effectiveness), thereby increasing their ROI while decreasing operational costs.

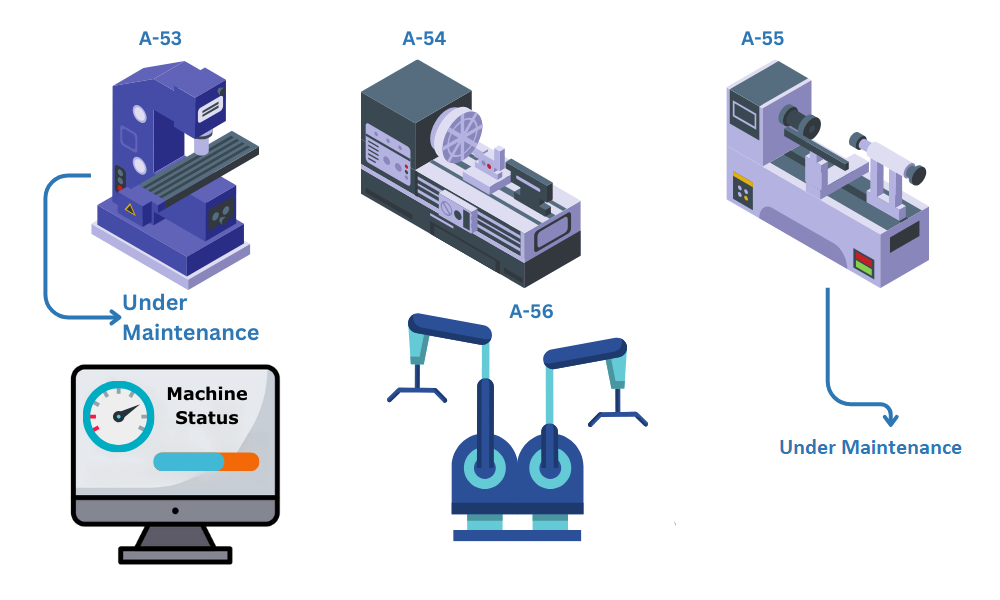

Instant insights can be monitored into the status and performance of assets and machines with Live Machine Dashboard. The status and positions of assets, equipment in real-time, giving a clear view of the current ongoing maintenance activity on desktop, laptop, mobile, tablet, etc.

Fast Maintenance Scheduler is responsible to take a maintenance plan and bring together all the resources needed to complete it. The Scheduling role involves assembling and coordinating the information, people, materials, equipment, along with all the other necessary resources to get the job done. Planned or scheduled maintenance is a list of predetermined maintenance checklist carried out at regular time intervals that are aimed at the prevention of breakdowns. The primary goal of scheduled maintenance is to prevent equipment failure before it actually occurs.

Prioritizing safety is paramount when it comes to maintenance operations. Fast Maintenance Management Software includes a robust Work Permit Management feature that not only streamlines the work authorization process but also significantly enhances safety protocols. It ensures that all maintenance tasks are conducted in a controlled and safe manner, reducing the risk of accidents or incidents associated with unauthorized or unsafe work practices. This feature provides peace of mind to maintenance teams and organizations by reinforcing a safety-first approach to maintenance operations.

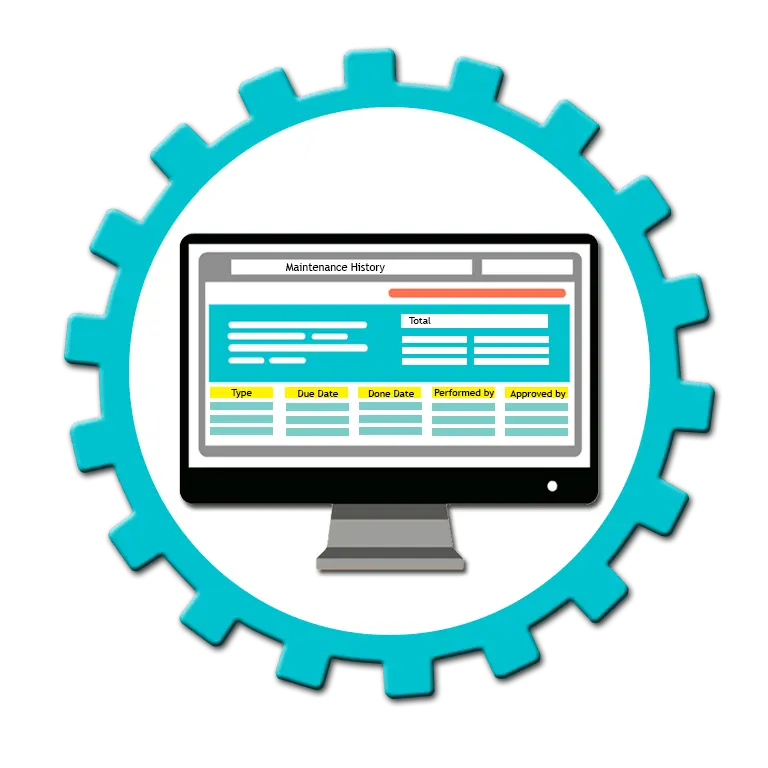

The Asset History is a report which shows the complete history of an asset. If a problem presents itself within your facility, you can easily track when this problem was last solved and to find any clues within the machine’s history that may indicate a more serious ongoing problem. Your CMMS system will keep track of when repairs were done and who they were done by, and this information will be recorded within that machine’s individual history log. Accessing these records allows technicians to have a better insight on a certain asset and to rely on the past experiences of other to better solve the problem at hand.

Fast Maintenance Software Techniques that many small businesses use to manage inventory: In Maintenance management software manage reorder point is a signal that informs when to place an order. This means you should place the order for replenishing the stock of inventory as soon as the level reaches.

❯ Use the FIFO approach (first in first out).

❯ Identify low-turn stock.

❯ Audit your stock.

❯ Use web-based inventory management software

❯ Track your stock levels at all times.

Fast Maintenance Management Software goes beyond basic asset management. It also keeps track of warranties and Annual Maintenance Contracts (AMCs) for spare parts. By alerting users to warranty expirations and AMC renewal dates, the software ensures that assets remain under warranty protection and are always serviced in a timely manner, helping organizations optimize costs and maintain operational efficiency.

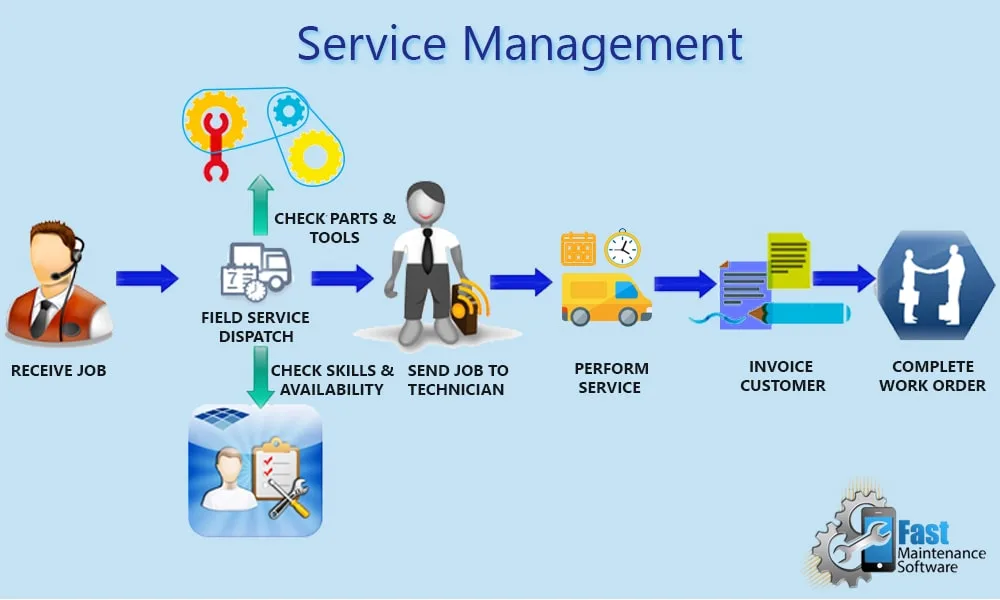

In the event of asset breakdowns or malfunctions, the software offers a seamless process for managing repairs. Maintenance teams can dispatch assets for repairs, monitor the repair progress, and receive them back after servicing. The reconciliation feature ensures that repaired assets are properly accounted for, reducing downtime and ensuring that equipment is always in optimal working condition.

In industry, total productive maintenance (TPM) is a system of maintaining and improving the integrity of production and quality systems through the machines, equipment, processes, and employees that add business value to an organization.

Software has identifies various reasons of stoppages of machines.Ths software has preventive maintenance facility which helps to reduces the stoppages of machines.

The software is facility to find out the OEE (Overall Equipment Effectiveness) which is indicating productive maintenance effectiveness.

Evolution of TPM

Break Down Maintenance : Restore equipment condition after break down

Preventive Maintenance : Regular inspection to see if anything is wrong. & Repair before break-down.

Productive Maintenance:Preventive Maintenance + Consideration of over-all efficiency and effectiveness of equipment.

T.P.M: Productive Maintenance +Total Participation of all concerned.

Measure maintenance team's effectiveness with KPI Dashboard, focusing on crucial metrics such as Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF). These metrics provide valuable insights into maintenance processes and help to make data-driven decisions for improvement.

A CMMS keeps you up-to-date organization’s maintenance activities. The software lets you store and attach procedures, error logs, manuals, permits, licenses, photos, images, diagrams, and schematics to the asset record.

Computerized maintenance management software aids organizations in regularly checking and maintaining equipment and meeting safety standards to prevent malfunction and critical failures.

Better scheduling means that your team isn’t sitting idle or working overtime, which means work can be distributed evenly.

Managing your inventory with a CMMS helps to track parts, manage suppliers and vendors, and optimize inventory levels. If stock falls below a set minimum, the system will notify the required users or suppliers to start the re-ordering process.

Inventory planning features give you the time to shop around for spare parts pricing, instead of having to buy in a hurry.

Maintenance management software tracks parts,history and other miscellaneous expenses when a maintenance work order is completed.

Fast Maintenance Management Software is used by organizations of all sizes in every market sector.

Here are the reasons you can depend on Fast solutions to keep you and your business up and running